Metalum CONtech provides cutting-edge technological packages designed to boost environmental sustainability, safety, and product quality, all while ensuring a swift return on investment. These solutions are tailored for both existing equipment upgrades and customized enhancements, facilitating seamless integration and reduced downtime.

A crucial component in continuous casting processes, enhancing the quality of the final product by improving the homogeneity of the molten metal.

Maintains a consistent metal level in the mould during the continuous casting process, ensuring high-quality output.

Essential for cooling and handling cast products, ensuring uniform cooling and minimizing deformation.

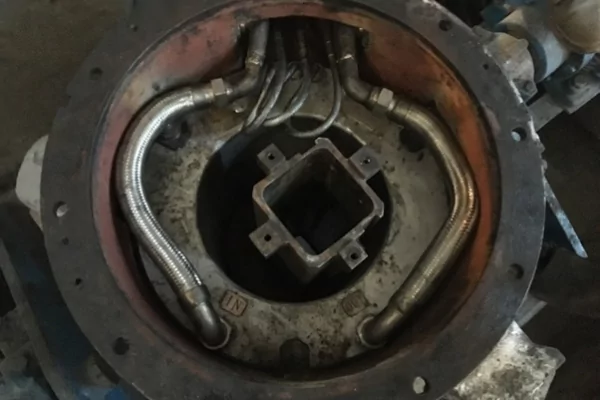

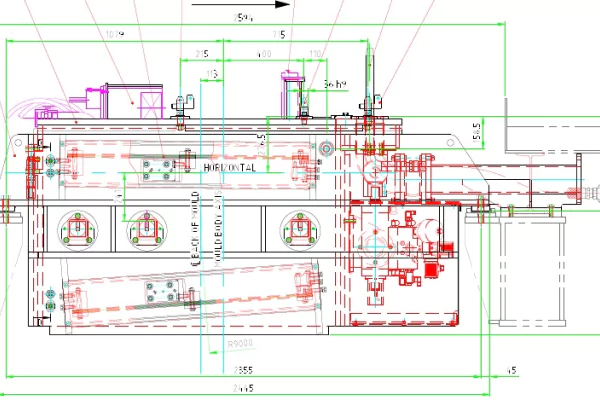

Designed to improve mould oscillation during casting, enhancing quality and efficiency.

Facilitates the seamless transfer of molten metal to the tundish.

Designed for precision cutting of cast products in continuous casting machines.

Ensures effective purging of the ladle to improve the quality of molten metal.

Designed for cutting hot billets with precision and efficiency.

Provides accurate measurement of molten metal, ensuring precise control over the casting process.

Ensures consistent and accurate feeding of casting powder into the mould.